Affordability plays a critical role in sourcing magnesium sulfate heptahydrate 99.5 for various applications. Pricing differences can significantly impact procurement decisions. For instance:

$1.92 for 500 gm of Magnesium Sulfate Heptahydrate 99.5% AR.

$27.23 for 6 units of Magnesium Sulfate Heptahydrate 99.5% for molecular biology, .

$73.63 for 1 unit of Magnesium Sulfate Heptahydrate GR for analysis.

$31.25 for 10 units of Magnesium Sulfate Heptahydrate 99.5% , each weighing 500 gm.

These variations stress the need to compare prices and suppliers carefully. A reliable supplier not only offers competitive pricing but also ensures consistent quality, making thoughtful evaluation a key strategy for cost savings.

Key Takeaways

Check prices from different sellers to get the best deal. This helps you know the usual cost and choose wisely.

Buy in large amounts to save money on each unit. Big orders can also lower shipping costs, helping you save more.

Watch for seasonal changes and demand to buy at the right time. Shopping during less busy times can save you a lot.

Make sure sellers have proper certifications to guarantee good quality. Trusted sellers follow global rules to keep products safe and effective.

Talk with sellers about payment and delivery options that work for you. Being flexible can make buying easier and better for your needs.

Key Factors Affecting Magnesium Sulfate Heptahydrate 99.5% Prices

Understanding the factors that influence magnesium sulfate heptahydrate 99.5% prices is essential for making informed purchasing decisions. These factors include purity and quality standards, packaging and shipping costs, and regional pricing variations based on supplier location.

Purity and Quality Standards

The purity of magnesium sulfate heptahydrate directly impacts its price. Higher purity levels, such as 99.5%, require advanced manufacturing processes and stringent quality control measures. For example, pharmaceutical-grade magnesium sulfate heptahydrate in the U.S. must meet USP specifications, ensuring heavy metal contamination remains below 0.1%. Achieving these standards often increases production costs. Indian suppliers, for instance, have faced shipment rejections due to arsenic levels exceeding 0.05 ppm, leading to an 8-15% rise in production expenses.

Compliance with international regulations also adds to the cost. Manufacturers in North America invest a median of $2.8 million in filtration systems to meet stricter EPA wastewater discharge limits. Similarly, the implementation of blockchain tracking systems for sulfuric acid sources under the EU’s revised REACH guidelines costs over $500,000. These investments ensure product quality but contribute to higher magnesium sulfate heptahydrate prices.

Tip: Buyers should verify the certifications and compliance standards of suppliers to ensure they receive high-quality products that meet regulatory requirements.

Packaging Options and Shipping Costs

Packaging plays a significant role in determining the price of magnesium sulfate heptahydrate. Suppliers offer various packaging options, ranging from 25kg bags to 1250kg bulk containers. Smaller packaging sizes often incur higher costs due to increased material usage and handling requirements. Bulk packaging, on the other hand, provides cost savings for large-scale buyers.

Shipping costs further influence prices. Factors such as distance, transportation mode, and fuel prices affect the overall cost of delivery. For instance, air freight is faster but more expensive than sea freight. Buyers should also consider the impact of packaging weight on shipping expenses. Lightweight yet durable materials can help reduce costs without compromising product safety during transit.

Note: Opting for bulk purchases and efficient shipping methods can significantly lower the overall cost of magnesium sulfate heptahydrate.

Supplier Location and Regional Pricing Variations

The location of a supplier significantly affects magnesium sulfate heptahydrate 99.5% prices. Production concentration in regions like China influences global supply and pricing dynamics. Regulatory frameworks in different regions also lead to variations in production costs. For example, stringent regulations in the European Union increase production costs by 15-20% for non-EU manufacturers, creating price disparities.

Demand in specific regions further impacts pricing strategies. Agricultural needs in South Asia and South America drive higher demand, affecting local prices. Non-compliance with EU regulations can result in shipment rejections, disrupting supply chains and increasing costs. Suppliers must also adhere to heavy metal content regulations to access certain markets, which influences their pricing strategies.

Insight: Buyers can explore alternative suppliers in regions with lower production costs to secure competitive prices while ensuring compliance with quality standards.

Market Demand and Seasonal Trends

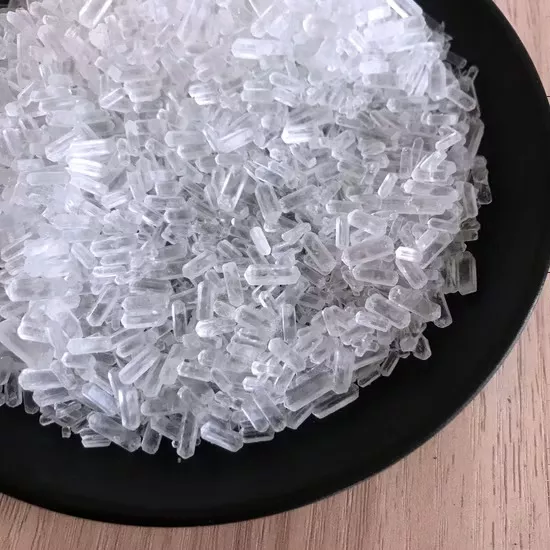

Market demand plays a pivotal role in shaping magnesium sulfate heptahydrate 99.5% prices. Industries such as agriculture, pharmaceuticals, and manufacturing rely heavily on this compound, driving fluctuations in its cost. For instance, agricultural applications, including soil enrichment and crop yield improvement, account for a significant portion of global demand. Farmers often purchase magnesium sulfate heptahydrate 99.5% in bulk to address magnesium deficiencies in soil, especially in regions with intensive farming practices. This high demand can lead to price surges, particularly during peak agricultural seasons.

Pharmaceutical and industrial sectors also contribute to demand variability. Magnesium sulfate heptahydrate 99.5% is a critical ingredient in medical treatments, such as Epsom salt baths and intravenous therapies. In industrial settings, it serves as a drying agent and a component in chemical synthesis. When these industries experience growth or supply chain disruptions, the resulting demand spikes can influence magnesium sulfate heptahydrate 99.5% prices.

Seasonal trends further amplify these fluctuations. In agriculture, demand typically peaks during planting and fertilization periods, such as spring and early summer in the Northern Hemisphere. During these months, farmers prioritize soil preparation and nutrient supplementation, increasing the need for magnesium sulfate heptahydrate. Conversely, demand may decline during off-seasons, leading to potential price reductions. Buyers who strategically time their purchases during these low-demand periods can secure more favorable pricing.

Global events and climatic conditions also impact seasonal demand. For example, droughts or extreme weather can deplete soil nutrients, prompting higher magnesium sulfate usage to restore soil health. Similarly, increased awareness of sustainable farming practices has led to a steady rise in demand for magnesium sulfate-based fertilizers, further influencing market dynamics.

Tip: Buyers should monitor industry trends and seasonal cycles to anticipate price changes. Aligning procurement strategies with low-demand periods can help reduce costs while ensuring a steady supply.

How to Compare Magnesium Sulfate Heptahydrate 99.5% Prices

Collecting Quotes from Multiple Suppliers

Comparing magnesium sulfate heptahydrate 99.5% prices begins with gathering quotes from various suppliers. Buyers should aim to collect pricing information from at least three suppliers to establish a clear understanding of the market range. This approach helps identify competitive rates and ensures informed decision-making.

When requesting quotes, buyers should specify their requirements, including the desired purity level (magnesium sulfate heptahydrate 99.5%), packaging size, and quantity. Clear communication minimizes misunderstandings and ensures accurate pricing. For instance, a supplier offering 25kg bags may quote a different price than one providing 1250kg bulk containers.

Tip: Buyers should inquire about additional details, such as lead times and payment terms, during the quote collection process. These factors can influence the overall cost and supplier selection.

Evaluating Bulk Discounts and Volume Pricing

Bulk orders often provide significant cost savings, making them an attractive option for businesses with high-volume needs. Suppliers frequently offer discounts for bulk purchases, which can reduce the unit price of magnesium sulfate heptahydrate 99.5%. For example, purchasing 10 tons of the product may result in a lower per-kilogram price compared to smaller quantities.

Buyers should carefully evaluate the pricing tiers offered by suppliers. Some suppliers provide incremental discounts based on order size, while others may offer flat-rate reductions for large purchases. Comparing these options helps buyers maximize their savings. Additionally, buyers should consider their storage capacity and usage rate to avoid overstocking, which could lead to unnecessary expenses.

Insight: Negotiating with suppliers for better discounts on bulk orders can further enhance cost efficiency, especially for long-term procurement plans.

Considering Additional Costs (Shipping, Taxes, etc.)

While the base price of magnesium sulfate heptahydrate 99.5% is crucial, additional costs like shipping costs, taxes, and customs duties can significantly impact the total expense. Buyers should account for these factors when comparing prices to avoid unexpected financial burdens.

Shipping costs vary based on factors such as distance, transportation mode, and packaging weight. For instance, sea freight is generally more economical for large shipments, while air freight offers faster delivery at a higher cost. Buyers should also consider the impact of packaging materials on shipping expenses. Lightweight yet durable options can help minimize costs without compromising product safety.

Taxes and customs duties differ by region and may affect the final price. Buyers importing magnesium sulfate heptahydrate 99.5% should familiarize themselves with local regulations to estimate these expenses accurately. Some suppliers include these costs in their quotes, while others list them separately. Clarifying this information ensures transparency and aids in accurate price comparisons.

Note: Buyers can reduce shipping costs by consolidating orders or partnering with suppliers located closer to their operations.

Comparing Payment Terms and Delivery Times

Payment terms and delivery times are critical factors when evaluating magnesium sulfate heptahydrate 99.5% suppliers. These elements directly affect cash flow, operational efficiency, and the overall procurement experience. Buyers should carefully assess these aspects to ensure they align with their business needs.

Payment Terms: Flexibility and Transparency

Suppliers often offer a range of payment terms, including advance payments, partial payments, or credit-based options. Each method has its advantages and potential drawbacks. For instance, advance payments may secure better pricing but can strain cash flow. On the other hand, credit terms provide flexibility, allowing buyers to allocate funds to other operational priorities. However, these terms may include interest or additional fees.

Buyers should prioritize suppliers that offer transparent payment policies. Clear documentation of payment schedules, penalties for late payments, and refund policies ensures a smooth transaction process. Additionally, negotiating payment terms tailored to specific business cycles can help optimize cash flow. For example, agricultural buyers might benefit from deferred payment options during off-seasons when revenue is lower.

Tip: Always confirm whether the supplier accepts multiple payment methods, such as wire transfers, credit cards, or digital payment platforms. This flexibility can simplify transactions and reduce processing delays.

Delivery Times: Speed and Reliability

Delivery times play a pivotal role in maintaining uninterrupted operations. Delays in receiving magnesium sulfate heptahydrate 99.5% can disrupt production schedules, leading to potential losses. Buyers should evaluate a supplier's ability to meet promised timelines consistently. Factors such as production capacity, inventory levels, and logistics partnerships influence delivery performance.

Suppliers with robust logistics networks often provide faster and more reliable delivery times. For instance, companies with multiple distribution centers or partnerships with reputable shipping carriers can ensure timely deliveries, even during peak demand periods. Buyers should also consider the supplier's proximity to their location, as shorter distances typically result in quicker shipments.

Insight: Requesting estimated delivery times during the quote collection process can help buyers compare suppliers effectively. Look for suppliers that offer tracking systems for real-time updates on shipment status.

Balancing Payment Terms and Delivery Times

Striking a balance between favorable payment terms and reliable delivery times is essential. A supplier offering extended credit terms but inconsistent delivery may not be the best choice. Conversely, a supplier with rapid delivery times but rigid payment policies could strain financial resources. Buyers should weigh these factors based on their operational priorities.

For example, businesses with tight production schedules might prioritize suppliers with shorter delivery times, even if it means stricter payment terms. Conversely, companies with flexible timelines may opt for suppliers offering extended payment options to improve cash flow. Open communication with suppliers can help identify mutually beneficial arrangements.

Note: Establishing long-term relationships with reliable suppliers often leads to improved payment terms and delivery times over time. Building trust can result in customized solutions that meet specific business needs.

Identifying Reliable Suppliers for Magnesium Sulfate Heptahydrate 99.5%

Checking Certifications and Compliance Standards

Certifications and compliance standards serve as critical indicators of a supplier's reliability. Buyers should prioritize suppliers that meet internationally recognized benchmarks for magnesium sulfate heptahydrate 99.5%. These certifications ensure product quality and adherence to safety regulations. For instance, suppliers complying with USP-NF and FCC standards maintain heavy metal limits below 10 ppm, making their products suitable for food-grade and pharmaceutical applications. Similarly, EU EFSA guidelines enforce stringent arsenic and lead limits, ensuring safe usage in agriculture and industrial processes.

Certification/Standard | Heavy Metal Limit | Compliance Requirement |

|---|---|---|

USP-NF | < 10 ppm | Food safety regulations |

FCC | < 10 ppm | Food safety regulations |

EU EFSA Guidelines | Arsenic: 3 ppm | Maximum limits for heavy metals |

Lead: 10 ppm | Maximum limits for heavy metals | |

China GB 29207-2012 | N/A | On-site facility audits required |

Suppliers holding these certifications demonstrate their commitment to quality and regulatory compliance. Buyers should request documentation to verify these credentials before finalizing procurement decisions.

Reviewing Customer Feedback and Testimonials

Customer feedback provides valuable insights into a supplier's performance and product reliability. Buyers should review testimonials and ratings from previous clients to assess the supplier's reputation. Positive reviews often highlight consistent product quality, timely deliveries, and responsive customer service. For example, industries relying on magnesium sulfate heptahydrate 99.5% for chemical synthesis frequently commend suppliers for delivering high-purity products that enhance reaction efficiency.

Negative feedback, on the other hand, can reveal potential issues such as delayed shipments or substandard packaging. Buyers should focus on patterns in reviews rather than isolated incidents to form a balanced perspective. Platforms like industry forums and supplier directories offer reliable sources for customer testimonials. Engaging directly with past clients can also provide firsthand accounts of the supplier's reliability.

Assessing Customer Support and Responsiveness

Effective customer support reflects a supplier's dedication to client satisfaction. Buyers should evaluate how promptly suppliers address inquiries and resolve issues. Reliable suppliers often provide 24-hour support systems, ensuring real-time assistance for order tracking and technical queries. For instance, Laizhou Baiyexin Chemical Co., Ltd. offers round-the-clock online support, enabling seamless communication with global clients.

Responsiveness during the procurement process is equally important. Suppliers who promptly provide quotes, clarify product specifications, and accommodate customization requests demonstrate professionalism. Buyers should also assess the supplier's ability to handle unforeseen challenges, such as shipment delays or regulatory changes. A proactive approach to problem-solving indicates a strong commitment to maintaining long-term partnerships.

Tip: Establishing clear communication channels with suppliers can streamline procurement and foster trust, ensuring a smooth purchasing experience.

Verifying Industry Experience and Reputation

Industry experience and reputation are critical factors when selecting suppliers for magnesium sulfate heptahydrate 99.5%. Buyers should prioritize suppliers with a proven track record in manufacturing and distributing high-quality chemical products. Companies with extensive experience often demonstrate a deeper understanding of industry standards and customer needs, ensuring reliable service and consistent product quality.

A supplier's longevity in the market reflects its ability to adapt to changing industry demands. For example, suppliers operating for over a decade typically possess robust production processes and established supply chains. These attributes minimize risks associated with delays or quality inconsistencies. Buyers should inquire about the supplier's history, including the number of years in operation and notable achievements within the industry.

Reputation serves as another vital indicator of reliability. Buyers can assess this by examining industry awards, partnerships, and affiliations with reputable organizations. Suppliers recognized for their contributions to the chemical sector often maintain higher standards of quality and compliance. Additionally, suppliers with strong reputations tend to attract repeat customers, further validating their credibility.

Networking within the industry provides valuable insights into supplier reliability. Buyers can consult peers or industry forums to gather recommendations. Engaging with professionals who have firsthand experience with specific suppliers helps identify trustworthy options. For instance, suppliers praised for their responsiveness and adherence to delivery schedules often stand out as reliable partners.

Tip: Buyers should request references from suppliers to verify their claims of industry experience and reputation. Speaking directly with previous clients offers a clearer picture of the supplier's capabilities and reliability.

By focusing on suppliers with extensive experience and positive reputations, buyers can reduce procurement risks and ensure a steady supply of magnesium sulfate heptahydrate 99.5%.

Practical Tips to Reduce Magnesium Sulfate Heptahydrate 99.5% Prices

Negotiating Deals with Suppliers

Negotiating effectively with suppliers can lead to significant cost reductions. Buyers should approach negotiations with a clear understanding of market trends and pricing benchmarks. Suppliers often appreciate long-term commitments, which can result in better pricing agreements. For instance, forming strategic partnerships with suppliers helps stabilize pricing and reduces market volatility. These collaborations address inefficiencies in the supply chain, benefiting both parties.

Buyers should also explore flexible payment terms or discounts for early payments. Suppliers offering such incentives often prioritize clients who demonstrate reliability. Open communication during negotiations fosters trust and increases the likelihood of securing favorable terms.

Tip: Buyers can leverage their purchasing history or projected order volumes to strengthen their negotiating position.

Buying in Bulk for Cost Savings

Purchasing magnesium sulfate heptahydrate 99.5% in bulk is one of the most effective ways to reduce costs. Suppliers frequently offer tiered pricing, where larger orders result in lower per-unit costs. For example, a buyer ordering 10 tons may pay significantly less per kilogram compared to smaller quantities. Bulk purchases also reduce packaging and shipping expenses, further enhancing savings.

However, buyers must consider storage capacity and product shelf life before committing to large orders. Proper planning ensures that bulk purchases align with operational needs without leading to overstocking. Suppliers with robust logistics networks can assist in scheduling deliveries to optimize storage utilization.

Insight: Buyers should evaluate suppliers' bulk pricing structures and negotiate additional discounts for recurring high-volume orders.

Timing Purchases Strategically

Strategic timing plays a crucial role in securing competitive prices. Buyers should monitor seasonal trends and market demand to identify periods of lower pricing. For instance, agricultural demand for magnesium sulfate heptahydrate 99.5% typically peaks during planting seasons, driving up prices. Purchasing during off-peak periods can yield significant savings.

Global events and production cycles also influence pricing. Collaborating with suppliers to understand their production schedules helps buyers plan purchases more effectively. Additionally, capacity-sharing agreements among producers stabilize regional prices, reducing the risk of sudden cost spikes.

Note: Buyers who align their procurement strategies with market trends and supplier production cycles can achieve substantial cost advantages.

Exploring Alternative Suppliers or Regions

Exploring alternative suppliers or sourcing regions can significantly impact the cost and availability of magnesium sulfate heptahydrate 99.5%. Buyers often find that diversifying their supplier base reduces dependency on a single source and opens opportunities for better pricing and service.

Benefits of Exploring Alternative Suppliers

Alternative suppliers may offer competitive pricing due to differences in production costs, regional demand, or operational efficiencies. For instance, suppliers in regions with lower labor costs or abundant raw materials often provide more affordable options. Additionally, working with multiple suppliers minimizes risks associated with supply chain disruptions, such as delays or shortages.

Buyers should evaluate potential suppliers based on their certifications, production capacity, and customer reviews. A supplier with a strong reputation and compliance with international standards ensures consistent quality. For example, companies like Baiyexin, which adhere to ISO and EU-REACH certifications, demonstrate reliability and commitment to excellence.

Regional Sourcing Opportunities

Sourcing magnesium sulfate heptahydrate 99.5% from different regions can also yield cost advantages. Countries with established chemical manufacturing industries, such as China and India, often produce high-quality products at competitive prices. Buyers should consider the trade-offs, such as shipping costs and delivery times, when sourcing from distant regions.

Local suppliers may offer faster delivery and reduced shipping expenses. However, their pricing might be higher due to regional production costs. Buyers must weigh these factors to determine the most cost-effective sourcing strategy.

Practical Steps for Buyers

Research suppliers in multiple regions and request detailed quotes.

Compare pricing, certifications, and delivery terms to identify the best options.

Establish relationships with suppliers that align with long-term procurement goals.

Tip: Buyers can leverage trade shows and online platforms to discover new suppliers and expand their sourcing network.

Understanding the factors influencing magnesium sulfate heptahydrate 99.5% prices and supplier reliability is essential for navigating the market effectively. Its hygroscopic nature complicates logistics, while volatile raw material costs and strict regulations impact profitability. Buyers who grasp these dynamics can make informed decisions that optimize procurement strategies.

Comparing prices and negotiating deals further enhances cost efficiency. A comparative market analysis highlights key factors such as pricing dynamics, supplier capabilities, and regional production efficiencies:

Factor | Description |

|---|---|

Pricing Dynamics | Insights into current market prices for magnesium sulfate heptahydrate 99.5, aiding in price negotiations. |

Supplier Capabilities | Evaluation of supplier strengths and production efficiencies, which can be leveraged in negotiations. |

Regional Production Efficiencies | Information on local production methods that reduce costs and improve logistics, enhancing negotiation leverage. |

By applying these strategies, buyers can secure affordable magnesium sulfate heptahydrate 99.5% while ensuring quality and reliability.

FAQ

What factors influence the price of magnesium sulfate heptahydrate 99.5%?

Several factors affect the price, including purity, packaging, shipping costs, and market demand. Seasonal trends and regional pricing variations also play a significant role in determining prices.

How can buyers find a reliable supplier for magnesium sulfate heptahydrate 99.5%?

Buyers should evaluate certifications, customer feedback, and industry experience. A supplier with a strong reputation and compliance with international standards ensures consistent quality and competitive prices.

Is it better to buy magnesium sulfate heptahydrate 99.5% in bulk?

Yes, bulk purchases often reduce the per-unit price and shipping costs. Buyers should assess their storage capacity and usage needs before committing to large orders.

What are the benefits of comparing prices from multiple suppliers?

Comparing prices helps buyers identify competitive rates and additional cost factors like shipping or taxes. This process ensures informed decisions and cost savings.

How can buyers reduce magnesium sulfate heptahydrate 99.5% prices?

Negotiating with suppliers, timing purchases strategically, and exploring alternative sourcing regions can help buyers secure lower prices without compromising quality.