Selecting the right magnesium sulfate heptahydrate manufacturer plays a crucial role in achieving operational efficiency and product effectiveness. This compound, projected to reach a market value of USD 286.84 million by 2033, is essential across industries like agriculture, food, and chemicals. With an expected growth rate of 0.42% CAGR from 2024 to 2033, the demand for reliable suppliers continues to rise. Manufacturers offering superior quality, regulatory compliance, and dependable delivery schedules help businesses maintain consistency in their applications. A thorough evaluation ensures that the heptahydrate meets specific requirements, minimizing risks and maximizing performance.

Key Takeaways

Check how pure and good the product is. Magnesium sulfate heptahydrate should be 99.5% pure or more for farming and food use.

Look for certifications that prove safety and care for nature. ISO 9001 and ISO 14001 show the supplier follows rules and is responsible.

Read customer reviews to learn about the supplier's reputation. Good feedback means the supplier is reliable and sells quality products.

Pick manufacturers with modern machines and automation. Automated systems make products faster and better, ensuring they arrive on time.

Choose suppliers who offer custom products and smart packaging. Custom options fit your needs and help reduce waste.

Key Factors to Evaluate in a Magnesium Sulfate Heptahydrate Manufacturer

Product Purity and Quality Standards

The purity of magnesium sulfate heptahydrate directly impacts its effectiveness in various applications. Manufacturers must adhere to stringent quality standards to ensure consistent product performance. High-purity levels, such as 99.5% or higher, are essential for industries like agriculture, food, and chemicals. Rigorous quality control processes, including multiple inspection procedures, help maintain these standards.

Market analysis highlights the importance of product quality in the Industrial Grade Magnesium Sulfate Heptahydrate Market. With a growing demand for reliable suppliers, manufacturers must prioritize purity and consistency to remain competitive. Businesses should evaluate product details, including particle size variations and grades, to match their specific needs.

Tip: Always request detailed product specifications and quality assurance reports from your supplier to verify purity levels and compliance with industry standards.

Certifications and Regulatory Compliance

Certifications and regulatory compliance demonstrate a manufacturer's commitment to safety, environmental responsibility, and industry standards. Leading magnesium sulfate heptahydrate manufacturers often hold certifications such as ISO 9001 for quality management and ISO 14001 for environmental practices. Compliance with EU-REACH regulations ensures traceability and safety in product sourcing.

The table below outlines key regulations and their implications for manufacturers:

Regulation | Description | Compliance Cost |

|---|---|---|

REACH (EU) | Requires full traceability of sulfuric acid sources | |

EPA (U.S.) | Stricter wastewater discharge limits for sulfate byproducts | $2.8 million median investment in filtration systems |

Manufacturers investing in these compliance measures demonstrate their reliability and commitment to sustainable practices. Businesses should prioritize suppliers with documented certifications to ensure adherence to global standards.

Reputation and Customer Feedback

A manufacturer's reputation reflects its reliability and the quality of its products. Positive customer feedback and testimonials provide valuable insights into a supplier's performance. Businesses should explore reviews and case studies to assess the consistency of delivery timelines, product quality, and customer service.

Reputable magnesium sulfate heptahydrate manufacturers often have a proven track record of meeting diverse client needs. Their ability to offer tailored solutions, such as customized packaging and application-specific grades, further enhances their credibility. Companies should prioritize suppliers with strong reputations to minimize risks and ensure long-term partnerships.

Note: Engage with industry forums and professional networks to gather unbiased opinions about potential suppliers.

Manufacturing Technology and Processes

The manufacturing technology and processes employed by magnesium sulfate heptahydrate manufacturers play a pivotal role in determining product quality, production efficiency, and environmental impact. Advanced technologies and streamlined workflows enable manufacturers to meet the growing demand for high-purity magnesium sulfate while adhering to stringent industry standards.

1. Automation and Precision in Production

Modern manufacturers rely on automated production lines to ensure consistency and precision. Fully automated systems reduce human error, enhance operational efficiency, and maintain uniformity across batches. For instance, companies like Baiyexin operate six automated production lines, achieving a daily output of 850 tons. This level of automation supports large-scale production without compromising quality.

Tip: Businesses should prioritize manufacturers with automated facilities to ensure consistent product quality and timely delivery.

2. Multi-Stage Quality Control Systems

High-quality magnesium sulfate heptahydrate requires rigorous quality control at every stage of production. Leading manufacturers implement multi-stage inspection procedures to monitor purity, particle size, and crystal water content. Baiyexin, for example, conducts 36 distinct quality checks to ensure that its products meet or exceed a 99.5% purity standard.

Quality Control Stage | Purpose | Example |

|---|---|---|

Raw Material Testing | Ensures purity of inputs | Sulfuric acid and magnesium sources |

In-Process Monitoring | Maintains consistency | Particle size and moisture levels |

Final Product Inspection | Verifies compliance with specs | Purity and grade certification |

This meticulous approach ensures that the final product aligns with customer requirements across industries.

3. Customization Through Advanced Processes

Manufacturers leverage advanced technologies to offer tailored solutions. Customization options include adjusting particle sizes, modifying crystal water content, and providing specialized packaging. These capabilities cater to diverse applications, such as agriculture, food processing, and industrial uses.

For example:

Agricultural Applications: Coarser particles for slow-release fertilizers.

Food Industry: Fine particles for enhanced solubility in food-grade products.

Note: Customization not only enhances product performance but also reduces waste, making it a cost-effective choice for businesses.

4. Sustainability and Eco-Friendly Practices

Sustainability has become a cornerstone of modern manufacturing. Many manufacturers adopt eco-friendly practices to minimize their environmental footprint. These include wastewater recycling, energy-efficient equipment, and reduced emissions. Baiyexin exemplifies this commitment by adhering to ISO 14001 standards and integrating sustainable practices into its operations.

🌱 Sustainability Spotlight:

Wastewater Recycling: Reduces water consumption by reusing treated water.

Energy Efficiency: Lowers energy usage through optimized production processes.

Emission Control: Implements filtration systems to limit air pollution.

By prioritizing sustainability, manufacturers not only comply with regulations but also appeal to environmentally conscious clients.

5. Innovation Through Patented Technologies

Innovation drives the magnesium sulfate industry forward. Manufacturers invest in research and development to create patented technologies that enhance product quality and production efficiency. Baiyexin, for instance, holds 24 patents, underscoring its leadership in technological advancements. These innovations enable the company to produce magnesium sulfate with superior purity and tailored properties.

Callout: Patented technologies often translate to better performance and reliability, making them a key factor when evaluating Magnesium Sulfate Heptahydrate Manufacturer.

Comparing Product Offerings Across Magnesium Sulfate Heptahydrate Manufacturers

Variations in Purity Levels and Grades

Magnesium sulfate heptahydrate manufacturers offer products with varying purity levels and grades to meet diverse industry requirements. High-purity options, such as 99.5% or higher, are essential for applications in agriculture, food processing, and pharmaceuticals. Manufacturers often provide industrial-grade, agricultural-grade, and food-grade variants, each tailored to specific uses.

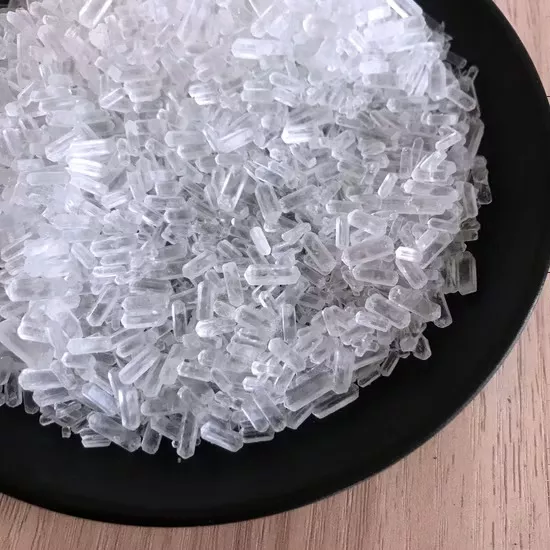

Product details, including particle size and crystal water content, play a crucial role in determining suitability for different applications. For example, finer particles enhance solubility in food-grade products, while coarser particles are preferred for slow-release fertilizers. Businesses should carefully evaluate these specifications to ensure compatibility with their operational needs.

Tip: Request detailed product specifications from Magnesium Sulfate Heptahydrate Manufacturer to verify purity levels and grade suitability for your intended application.

Packaging Options and Customization

Packaging options and customization capabilities vary significantly among magnesium sulfate heptahydrate manufacturers. Leading Magnesium Sulfate Heptahydrate Manufacturer offer tailored solutions to meet specific client requirements, ensuring optimal storage, transportation, and application efficiency.

Customized packaging options include:

Material Details: Durable packaging materials to prevent contamination.

Size Variations: Bulk packaging for industrial use or smaller units for retail.

Procurement Costs: Cost-effective solutions for large-scale orders.

Manufacturers like Baiyexin provide flexible packaging options, allowing clients to specify dimensions, labeling, and sealing methods. These features enhance product usability and reduce waste, making them ideal for businesses with unique operational demands.

Callout: Customization not only improves product handling but also aligns packaging with branding and regulatory requirements.

Application-Specific Versatility

Magnesium sulfate heptahydrate demonstrates remarkable versatility across various applications. Manufacturers optimize their products to cater to industry-specific needs, ensuring consistent performance and reliability.

Aspect | Findings |

|---|---|

Crystallization Process | Studied using terahertz time-domain spectroscopy (THz-TDS). |

Concentration Effects | Higher initial concentration leads to erratic crystal growth. |

Temperature Effects | Elevated temperatures above 6 °C result in faster crystal growth. |

Stages of Crystallization | Three distinct stages observed during the crystallization process. |

Application Context | Relevant for environmental analysis and pharmaceutical applications. |

These findings highlight the importance of product details, such as purity and crystallization properties, in determining application success. For instance, magnesium sulfate heptahydrate is widely used in agriculture to improve soil quality and in pharmaceuticals for its therapeutic benefits. Manufacturers offering tailored solutions for specific industries stand out as reliable partners.

Note: Businesses should assess product versatility to ensure compatibility with their operational goals and industry standards.

Environmental and Sustainability Practices

Sustainability has become a critical factor in evaluating magnesium sulfate heptahydrate manufacturers. Companies that prioritize eco-friendly practices not only reduce their environmental footprint but also align with global efforts to combat climate change. These practices enhance the appeal of their product to environmentally conscious clients.

Many manufacturers adopt advanced technologies to minimize waste and optimize resource utilization. For instance, wastewater recycling systems allow the reuse of treated water, significantly reducing water consumption. Energy-efficient equipment further lowers operational costs while decreasing greenhouse gas emissions. These measures ensure that the production of heptahydrate remains both cost-effective and environmentally responsible.

Certifications like ISO 14001 demonstrate a manufacturer's commitment to sustainable practices. This certification ensures that companies adhere to strict environmental management standards. Additionally, compliance with regulations such as EU-REACH guarantees the safe sourcing and handling of raw materials. These certifications provide clients with confidence in the product's safety and sustainability.

Manufacturers also focus on reducing packaging waste by offering customizable options. Tailored packaging solutions not only meet specific client needs but also minimize material usage. For example, bulk packaging reduces the overall environmental impact compared to smaller, single-use containers. These efforts reflect a commitment to sustainability while addressing practical business requirements.

The integration of sustainable practices into production processes benefits both the environment and the end-users. By choosing manufacturers that prioritize eco-friendly methods, businesses can ensure that their product details align with their corporate social responsibility goals. This approach fosters long-term partnerships and supports global sustainability initiatives.

Practical Tips for Selecting the Best Magnesium Sulfate Heptahydrate Manufacturer

Assessing Supplier Reliability and Delivery Timelines

Reliability is a cornerstone when evaluating a magnesium sulfate heptahydrate manufacturer. A dependable supplier ensures consistent delivery schedules and maintains the quality of the product across all batches. Businesses should prioritize manufacturers with a proven track record of meeting deadlines and adhering to promised specifications.

Several indicators can help assess Magnesium Sulfate Heptahydrate Manufacturer reliability. Certifications such as ISO 9001 and EU-REACH validate a supplier's commitment to quality and regulatory compliance. Customer testimonials and industry awards also provide valuable insights into a Magnesium Sulfate Heptahydrate Manufacturer performance. These elements reflect the supplier's ability to meet delivery timelines and maintain high standards.

Tip: Collaborate with Magnesium Sulfate Heptahydrate Manufacturer who demonstrate transparency in their operations and provide regular updates on order progress. This approach minimizes risks and ensures smooth supply chain management.

Evaluating Customization Capabilities and Bulk Order Options

Customization plays a vital role in meeting specific operational needs. Leading magnesium sulfate heptahydrate manufacturers offer tailored solutions, including adjustments to particle size, crystal water content, and packaging options. These capabilities allow businesses to optimize the product for their unique applications, whether in agriculture, food processing, or industrial use.

Bulk order options are equally important for businesses requiring large quantities. Manufacturers equipped with advanced production facilities can handle high-volume orders without compromising quality. For instance, companies like Baiyexin, with a daily production capacity of 850 tons, exemplify the ability to meet bulk order demands efficiently.

Callout: Customization and bulk order capabilities not only enhance operational efficiency but also reduce costs by minimizing waste and ensuring precise product specifications.

Balancing Cost with Quality and Service

Cost considerations often influence Magnesium Sulfate Heptahydrate Manufacturer selection, but businesses must balance affordability with quality and service. Low-cost options may compromise product quality, leading to inefficiencies and potential losses. Instead, businesses should evaluate the overall value offered by a supplier, including product quality, customer support, and delivery reliability.

High-quality magnesium sulfate heptahydrate ensures consistent performance across applications. Manufacturers that invest in advanced technologies and rigorous quality control processes deliver products with superior purity and reliability. Additionally, responsive customer service enhances the overall experience, addressing concerns promptly and ensuring satisfaction.

Note: Prioritize suppliers who offer competitive pricing without sacrificing quality or service. This approach ensures long-term benefits and minimizes operational risks.

Importance of Transparent Communication and Support

Transparent communication and robust support systems form the foundation of successful supplier relationships. Businesses rely on clear and consistent communication to ensure that their operational needs are met without disruptions. Manufacturers who prioritize transparency foster trust and long-term partnerships, enabling clients to make informed decisions.

1. Benefits of Transparent Communication

Transparent communication allows businesses to access critical information about product specifications, delivery timelines, and pricing structures. Magnesium Sulfate Heptahydrate Manufacturer who provide detailed updates on production progress and shipment schedules help clients plan their operations effectively. This level of openness minimizes uncertainties and ensures smooth supply chain management.

Key benefits include:

Improved Decision-Making: Access to accurate data enables businesses to align procurement strategies with operational goals.

Risk Mitigation: Early identification of potential delays or issues reduces the likelihood of disruptions.

Enhanced Collaboration: Open dialogue fosters mutual understanding and strengthens partnerships.

Tip: Choose suppliers who offer regular updates and maintain open channels for communication. This approach ensures that businesses remain informed at every stage of the procurement process.

2. Role of Customer Support in Magnesium Sulfate Heptahydrate Manufacturer Relationships

Customer support plays a pivotal role in addressing concerns and resolving issues promptly. Reliable suppliers invest in dedicated support teams to assist clients with inquiries related to product customization, bulk orders, and regulatory compliance. These teams act as a bridge between the manufacturer and the client, ensuring seamless communication and problem-solving.

Effective customer support includes:

Technical Assistance: Guidance on product specifications and application compatibility.

Order Tracking: Real-time updates on shipment status and delivery timelines.

Issue Resolution: Prompt responses to complaints or discrepancies in product quality.

Magnesium Sulfate Heptahydrate Manufacturer like Baiyexin exemplify this commitment by offering tailored solutions and responsive support services. Their ability to address client needs efficiently enhances the overall experience and builds trust.

3. Importance of Proactive Communication

Proactive communication goes beyond responding to inquiries. It involves anticipating client needs and providing solutions before challenges arise. Magnesium Sulfate Heptahydrate Manufacturer who adopt this approach demonstrate their dedication to customer satisfaction and operational excellence.

Examples of proactive communication include:

Forecasting Demand: Sharing insights on market trends to help clients plan inventory.

Offering Recommendations: Suggesting product variants or customization options based on client requirements.

Providing Alerts: Informing clients about regulatory changes or industry developments that may impact procurement.

Callout: Proactive communication not only strengthens supplier relationships but also positions manufacturers as reliable partners in business growth.

4. Evaluating Transparency and Support Systems

Businesses should assess a supplier's communication and support capabilities during the selection process. Key indicators include responsiveness, clarity in documentation, and the availability of dedicated support channels. Suppliers who prioritize transparency and offer comprehensive support services stand out as dependable partners.

Evaluation Criteria | Description | Example |

|---|---|---|

Responsiveness | Timely replies to inquiries | Email response within 24 hours |

Documentation Clarity | Detailed product specifications and contracts | Purity levels and packaging details |

Support Availability | Access to technical and customer support teams | 24/7 helpline for urgent queries |

By focusing on these criteria, businesses can identify Magnesium Sulfate Heptahydrate Manufacturer who align with their operational needs and values.

Transparent communication and strong support systems are essential for building trust and ensuring operational success. Manufacturers who excel in these areas empower businesses to achieve their goals while minimizing risks.

Evaluating a magnesium sulfate heptahydrate manufacturer requires a focus on quality, certifications, and reliability. Businesses should align Magnesium Sulfate Heptahydrate Manufacturer offerings with specific application needs to ensure compatibility and maximize efficiency. Strategic partnerships with research institutions and agricultural cooperatives enhance co-creation efforts. Data-driven marketing strategies help suppliers tailor products to regional demand patterns and customer needs. Companies should prioritize transparent communication and proactive support systems to build trust and ensure smooth operations. Selecting a supplier with these attributes fosters long-term success and operational excellence.

FAQ

What is the significance of purity levels in magnesium sulfate heptahydrate?

Purity levels determine the compound's effectiveness in specific applications. High-purity magnesium sulfate, such as 99.5%, ensures optimal performance in agriculture, food processing, and industrial uses. Manufacturers achieve this through rigorous quality control processes, enhancing reliability and consistency.

How do certifications impact Magnesium Sulfate Heptahydrate Manufacturer selection?

Certifications validate a manufacturer's adherence to industry standards. ISO 9001 ensures quality management, while ISO 14001 reflects environmental responsibility. EU-REACH compliance guarantees product safety. These certifications build trust and demonstrate a Magnesium Sulfate Heptahydrate Manufacturer's commitment to excellence.

Can magnesium sulfate heptahydrate be customized for specific applications?

Yes, leading manufacturers offer customization options. Adjustments include particle size, crystal water content, and packaging. These tailored solutions enhance compatibility with diverse applications, such as agriculture, pharmaceuticals, and food processing, ensuring optimal results.

Why is sustainability important in magnesium sulfate production?

Sustainability reduces environmental impact and aligns with global climate goals. Eco-friendly practices, such as wastewater recycling and energy-efficient equipment, minimize waste and emissions. Manufacturers with ISO 14001 certification demonstrate their commitment to sustainable operations.

How can businesses assess Magnesium Sulfate Heptahydrate Manufacturer reliability?

Businesses should evaluate delivery timelines, customer feedback, and certifications. Reliable Magnesium Sulfate Heptahydrate Manufacturer maintain consistent quality and meet deadlines. Transparency in communication and proactive support further strengthen supplier relationships, ensuring smooth operations.