Ensuring optimal quality from magnesium sulfate anhydrous suppliers is critical to maintaining its reliability and performance in a variety of applications. Addressing impurities, hygroscopicity, and other challenges can safeguard its effectiveness and value.

Magnesium sulfate anhydrous plays a vital role in numerous industries, offering unparalleled versatility and functionality. Its applications span agriculture, pharmaceuticals, and chemical manufacturing, where it contributes to soil enrichment, therapeutic formulations, and industrial processes.

Several factors highlight the importance of magnesium sulfate anhydrous suppliers:

Solid magnesium sulfate dominated over 72.3% of the global market share in 2023, reflecting its widespread adoption.

Fertilizer applications accounted for 33.4% of the market, highlighting its critical role in agriculture.

The global market is projected to grow from USD 903.4 million in 2023 to USD 1,485.6 million by 2033, with a 5.1% CAGR.

Key Takeaways

Magnesium sulfate anhydrous is important for farming, medicine, and making chemicals. It improves soil and makes products work better.

Keeping it very pure (≥99.5%) is key for it to work well in delicate uses.

Store it in dry places with cool temperatures to stop it from soaking up water and to keep it good.

Careful manufacturing and strict quality checks reduce dirt and keep it working the same every time.

Picking a trusted magnesium sulfate anhydrous supplier like Laizhou Baiyexin ensures it meets global rules, making it safer and more reliable.

Understanding Magnesium Sulfate Anhydrous

Definition and Key Applications

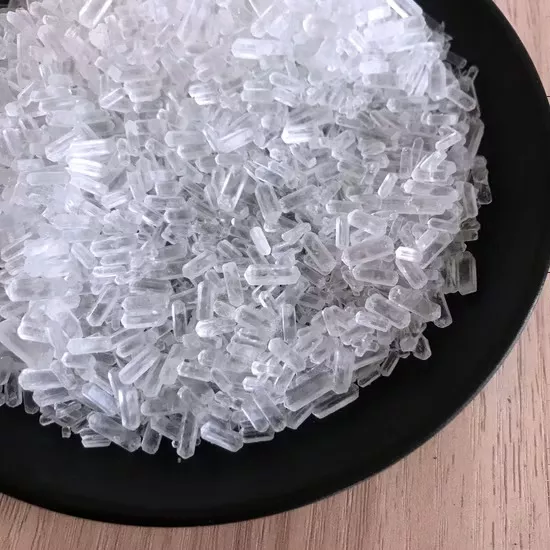

Magnesium sulfate anhydrous, often referred to as the anhydrous form of Epsom salt, is a chemical compound widely recognized for its versatility across industries. Unlike its hydrated counterpart, the anhydrous form contains no water molecules, making it particularly suitable for applications requiring high purity and stability.

Its primary use lies in agriculture, where it serves as a vital fertilizer to address magnesium deficiencies in soil. Magnesium plays a critical role in chlorophyll production and photosynthesis, directly impacting plant health and crop yield. Beyond agricultural applications, magnesium sulfate anhydrous finds use in pharmaceuticals, where it acts as a key ingredient in therapeutic formulations, and in chemical manufacturing, where it serves as a drying agent and catalyst.

Key Facts About Industrial Relevance:

Magnesium sulfate is essential for improving soil fertility in agriculture.

By the mid-1970s, the production volume of magnesium sulfate monohydrate reached 2.3 million tons annually, reflecting its widespread demand.

Importance of Quality Standards for Magnesium Sulfate Anhydrous Suppliers

The strict quality standards of magnesium sulfate anhydrous suppliers ensure the reliability and effectiveness of anhydrous magnesium sulfate in critical applications.Industries such as agriculture and pharmaceuticals demand high levels of purity and consistency to achieve optimal results.

The following table outlines key quality benchmarks for magnesium sulfate anhydrous:

Quality Control Aspect | Standard/Method |

|---|---|

Purity Assessment | USP standards of ≥99.5% purity |

Analytical Method | Potentiometric titration with EDTA for Mg²⁺ content |

Analytical Method | Gravimetric analysis via barium chloride precipitation for sulfate purity |

Adherence to these standards by magnesium sulfate anhydrous suppliers ensures that the anhydrous magnesium sulfate meets the stringent requirements of its various applications. For instance, in agricultural applications, high purity guarantees that crops receive the necessary nutrients without harmful contaminants. Similarly, in pharmaceutical formulations, precise quality control safeguards patient safety and product efficacy.

Identifying Quality Issues with Common Magnesium Sulfate Anhydrous Suppliers

Impurities and contaminants issues for magnesium sulfate anhydrous suppliers

Impurities and contaminants pose significant challenges to the performance and reliability of magnesium sulfate anhydrous. These unwanted substances can originate from raw materials, manufacturing processes, or external environmental factors. Even trace amounts of impurities can compromise the compound's effectiveness, particularly in sensitive applications like pharmaceuticals and agriculture.

For example, in agricultural use, contaminants may introduce harmful elements into the soil, potentially affecting crop health. Similarly, in pharmaceutical formulations, impurities can alter the chemical stability of the product, jeopardizing patient safety. To mitigate these risks, manufacturers must implement rigorous purification processes and adhere to strict quality control protocols.

Hygroscopicity issues of magnesium sulfate anhydrous suppliers

Magnesium sulfate anhydrous is highly hygroscopic, meaning it readily absorbs moisture from its surroundings. This property makes it vulnerable to environmental conditions, which can lead to clumping, reduced purity, and diminished effectiveness. Proper storage and handling are critical to maintaining its quality.

Key environmental factors influencing moisture absorption include:

Relative humidity should be controlled between 45% and 75%.

Materials must not be stored at unqualified moisture levels.

Failure to meet these conditions can result in the rehydration of the compound, transforming it into its hydrated form and reducing its suitability for applications requiring anhydrous properties. Manufacturers and distributors must prioritize optimized storage solutions to preserve the integrity of the product.

Particle size inconsistency problem among magnesium sulfate anhydrous suppliers

Particle size plays a crucial role in determining the performance of magnesium sulfate anhydrous across various applications. In agriculture, for instance, uniform particle size ensures even distribution in soil, promoting consistent nutrient absorption by plants. In contrast, irregular particle sizes can lead to uneven application, reducing the compound's effectiveness.

In industrial processes, particle size affects solubility and reaction rates. Larger particles may dissolve more slowly, while excessively fine particles can lead to dust formation, posing handling and safety challenges. To address these issues, magnesium sulfate anhydrous suppliers employ advanced sieving and milling techniques to achieve precise particle size specifications. Regular quality checks further ensure consistency, meeting the diverse needs of end-users.

The root cause of quality problems of magnesium sulfate anhydrous suppliers

Manufacturing process limitations of magnesium sulfate anhydrous suppliers

Magnesium Sulfate Anhydrous Suppliers The production of anhydrous magnesium sulfate requires precision and adherence to strict procedures. Deviations in the production process often lead to quality issues. For instance, insufficient purification steps can leave trace impurities in the final product. Inconsistent temperature control during crystallization may result in variations in particle size or purity.

Tip: magnesium sulfate Anhydrous supplier adopts advanced manufacturing technology, such as automated systems, help minimize human error and ensure consistent quality.

Magnesium sulfate anhydrous suppliers must also address equipment maintenance. Outdated machinery can introduce contaminants or fail to meet modern production standards. Regular inspections and upgrades are essential to maintain optimal performance.

Storage and handling errors by magnesium sulfate anhydrous suppliers

Improper storage and handling practices significantly impact the quality of magnesium sulfate anhydrous. Its hygroscopic nature makes it highly susceptible to moisture absorption, which can compromise its anhydrous properties.

Key storage errors include:

Inadequate Packaging: Poorly sealed containers allow moisture infiltration.

Uncontrolled Environments: High humidity or fluctuating temperatures accelerate degradation.

Handling errors, such as exposure to open air during transportation, further exacerbate these issues. magnesium sulfate anhydrous suppliers and distributors must implement robust storage protocols, including climate-controlled facilities and moisture-resistant packaging.

Note: Proper training for personnel handling magnesium sulfate anhydrous reduces the risk of contamination or damage during transit.

Supply Chain Vulnerabilities of Magnesium Sulfate Anhydrous Suppliers

Supply chain inefficiencies often contribute to quality inconsistencies. Delays in transportation expose the product to varying environmental conditions, increasing the risk of moisture absorption or contamination.

Common vulnerabilities include:

Unreliable Magnesium Sulfate Anhydrous Suppliers: Raw materials sourced from inconsistent suppliers may introduce impurities.

Inadequate Logistics: Poorly managed transportation networks fail to protect the product during transit.

Collaborating with trusted Magnesium Sulfate Anhydrous Suppliers and investing in efficient logistics systems ensures the product maintains its integrity from production to delivery.

Callout: A streamlined supply chain reduces risks and enhances customer satisfaction by delivering high-quality magnesium sulfate anhydrous consistently.

Effective Solutions for Quality Assurance

Advanced Manufacturing Practices

Implementing advanced manufacturing practices ensures magnesium sulfate anhydrous meets the highest quality standards. Modern production facilities utilize automated systems to minimize human error and maintain consistency. These systems monitor critical parameters such as temperature, pressure, and purity levels throughout the manufacturing process.

Innovative technologies, such as continuous crystallization and high-efficiency filtration, enhance product uniformity. These methods reduce impurities and ensure precise particle size distribution. Manufacturers also invest in real-time analytics to detect and address deviations immediately. This proactive approach prevents defects and guarantees a reliable final product.

Tip: Regularly upgrading manufacturing equipment and training personnel on the latest techniques further enhances production efficiency and product quality.

Optimized Packaging and Storage Solutions

Proper packaging and storage solutions play a pivotal role in preserving the integrity of magnesium sulfate anhydrous. Its hygroscopic nature requires specialized packaging to prevent moisture absorption. High-quality, moisture-resistant materials, such as multi-layered polyethylene bags, provide an effective barrier against environmental factors.

Storage facilities must maintain controlled conditions to safeguard the product. Ideal environments include low humidity levels and stable temperatures. For large-scale storage, climate-controlled warehouses equipped with dehumidifiers offer optimal protection.

Packaging options tailored to specific needs, such as 25kg, 50kg, or jumbo bags, enhance convenience for end-users. These solutions cater to diverse industries, including agriculture, where magnesium sulfate anhydrous is widely used as a fertilizer. Proper handling protocols during transportation further ensure the product reaches customers in pristine condition.

Callout: Optimized packaging and storage not only preserve product quality but also contribute to enhancing agricultural efficiency by delivering consistent results in the field.

Comprehensive Quality Control Systems

Comprehensive quality control systems are essential for maintaining the reliability of magnesium sulfate anhydrous across applications. These systems involve rigorous testing at every stage of production, from raw material sourcing to final packaging. Analytical methods, such as potentiometric titration and gravimetric analysis, verify the compound's purity and composition.

Magnesium sulfate anhydrous suppliers also implement batch tracking to ensure traceability. This practice identifies potential issues and facilitates swift corrective actions. Regular audits and certifications, such as ISO9001 and REACH compliance, further demonstrate a commitment to excellence.

Advanced laboratories equipped with state-of-the-art instruments enable precise testing. These facilities assess critical parameters, including particle size, moisture content, and impurity levels. By adhering to stringent quality standards, manufacturers deliver a product that meets the diverse needs of industries ranging from pharmaceuticals to agriculture.

Note: A robust quality control system not only ensures compliance with international standards but also builds trust with customers by consistently delivering high-quality magnesium sulfate anhydrous.

Why Choose Laizhou Baiyexin Chemical Co., Ltd. magnesium sulfate anhydrous suppliers?

Stringent Quality Control Measures

Laizhou Baiyexin Chemical Co., Ltd. Magnesium Sulfate Anhydrous Suppliers prioritizes quality at every stage of production. Each batch of Magnesium Sulfate Anhydrous undergoes 36 rigorous quality checks to ensure it meets the highest standards. These checks verify purity, particle size, and moisture content, guaranteeing a product that performs reliably across industries.

The company’s adherence to global certifications, including ISO 9001, ISO 14001, and ISO 45001, reflects its commitment to safety, efficiency, and environmental responsibility. These certifications demonstrate that their processes align with international benchmarks, ensuring consistent quality for customers worldwide.

Callout: Industries commend Laizhou Baiyexin for delivering high-purity products that enhance reaction efficiency and meet diverse application needs.

Customization Options for Diverse Applications

Laizhou Baiyexin Chemical Co., Ltd. offers tailored solutions to meet the unique requirements of its customers. Their Magnesium Sulfate Anhydrous can be customized for purity, particle size, and packaging, making it suitable for a wide range of applications.

For agriculture, their fertilizers stand out for their high purity (99.5%) and customizable sizes, which enhance precision farming practices. This adaptability ensures optimal results for crops like citrus, berries, tomatoes, and peppers.

Fertilizer Type | Cost per Ton ($) | Key Features | Best Use Cases |

|---|---|---|---|

BaiYeXin Magnesium Sulfate | 450-500 | High purity, customizable sizes | Citrus, berries, tomatoes, peppers |

This flexibility allows customers to achieve superior outcomes, whether in agriculture, pharmaceuticals, or chemical manufacturing.

Certifications and Compliance with International Standards

Laizhou Baiyexin Chemical Co., Ltd. maintains compliance with international standards, ensuring its products meet the stringent requirements of global markets. Certifications such as EU-REACH, HALAL, and KOSHER further validate the safety and quality of their Magnesium Sulfate Anhydrous.

These certifications not only demonstrate the company’s dedication to quality but also expand its reach to diverse industries and regions. Customers can trust that every product adheres to strict safety and environmental guidelines, making it a reliable choice for critical applications.

Tip: Choosing a certified supplier like Laizhou Baiyexin ensures compliance with global standards and enhances product reliability.

Flexible Packaging and Reliable Customer Support

Laizhou Baiyexin Chemical Co., Ltd. understands the critical role of packaging in preserving the quality of magnesium sulfate anhydrous. Their packaging solutions are designed to protect the product from environmental factors, ensuring it reaches customers in optimal condition. The company offers a variety of packaging options, including 25kg, 50kg, and jumbo bags, catering to the diverse needs of industries such as agriculture, pharmaceuticals, and chemical manufacturing.

Proper packaging materials, such as moisture-proof polyethylene bags with tight seals, prevent contamination and moisture absorption during storage and transportation. These measures maintain the anhydrous properties of magnesium sulfate, ensuring its effectiveness in applications requiring high purity and stability. Industries relying on magnesium sulfate heptahydrate have praised suppliers for delivering high-purity products that enhance reaction efficiency, further validating the importance of reliable packaging.

Tip: Choosing packaging tailored to specific requirements minimizes waste and ensures efficient handling during transportation.

Customer support is another cornerstone of Laizhou Baiyexin's operations. The company provides 24-hour online assistance, enabling seamless communication with clients worldwide. Their prompt responses to inquiries and swift resolution of issues demonstrate a strong commitment to customer satisfaction. Positive reviews frequently highlight the company's consistent product quality, timely deliveries, and responsive service, reinforcing its reputation as a trusted supplier.

Key Features of Laizhou Baiyexin's Packaging and Support:

Moisture-resistant materials for product safety.

Flexible packaging sizes for diverse applications.

24/7 customer service for global clients.

By combining advanced packaging solutions with exceptional customer support, Laizhou Baiyexin Chemical Co., Ltd. ensures a seamless experience for its clients. These efforts not only safeguard product quality but also build long-term trust and reliability in the industry.

Ensuring the quality of magnesium sulfate anhydrous is vital for its effectiveness in agriculture and other industries. Impurities, moisture absorption, and particle size inconsistencies can compromise its performance, affecting crop health and industrial processes. Addressing these challenges requires advanced manufacturing practices, optimized packaging, and robust quality control systems.

Laizhou Baiyexin Chemical Co., Ltd. stands out for its commitment to excellence. Their products meet stringent standards, including USP-NF and FCC certifications, ensuring heavy metal limits below 10 ppm. Positive reviews frequently highlight consistent quality, timely deliveries, and responsive customer service.

Certification/Standard | Heavy Metal Limit | Compliance Requirement |

|---|---|---|

USP-NF | < 10 ppm | Food safety regulations |

FCC | < 10 ppm | Food safety regulations |

EU EFSA Guidelines | Arsenic: 3 ppm | Maximum limits for heavy metals |

Lead: 10 ppm | Maximum limits for heavy metals | |

China GB 29207-2012 | N/A | On-site facility audits required |

Choosing Laizhou Baiyexin magnesium sulfate anhydrous suppliers ensures reliability, adaptability, and superior customer support. Their 24-hour online assistance facilitates seamless communication, reflecting a strong commitment to client satisfaction. Requesting a quote or sample allows customers to experience the difference in quality firsthand.

FAQ

What is magnesium sulfate anhydrous used for?

Magnesium sulfate anhydrous serves as a fertilizer in agriculture, a drying agent in chemical manufacturing, and a component in pharmaceutical formulations. Its versatility makes it essential for industries requiring high purity and stability.

How should magnesium sulfate anhydrous be stored?

Store magnesium sulfate anhydrous in moisture-resistant packaging within climate-controlled environments. Maintain low humidity and stable temperatures to preserve its anhydrous properties and prevent contamination.

Can magnesium sulfate anhydrous be customized for specific applications?

Yes, magnesium sulfate anhydrous suppliers offer customization options for purity, particle size, and packaging. These tailored solutions ensure optimal performance across diverse industries, including agriculture and pharmaceuticals.

What certifications ensure the quality of magnesium sulfate anhydrous?

Certifications like ISO9001, REACH, HALAL, and KOSHER validate the safety and quality of magnesium sulfate anhydrous. These standards guarantee compliance with international regulations and industry requirements.

Why is particle size important in magnesium sulfate anhydrous?

Particle size affects solubility, distribution, and reaction rates. Uniform sizes ensure consistent application in agriculture and efficient processing in industrial uses.